100 years of the Cyclo® gear

Explore the technology behind the invention

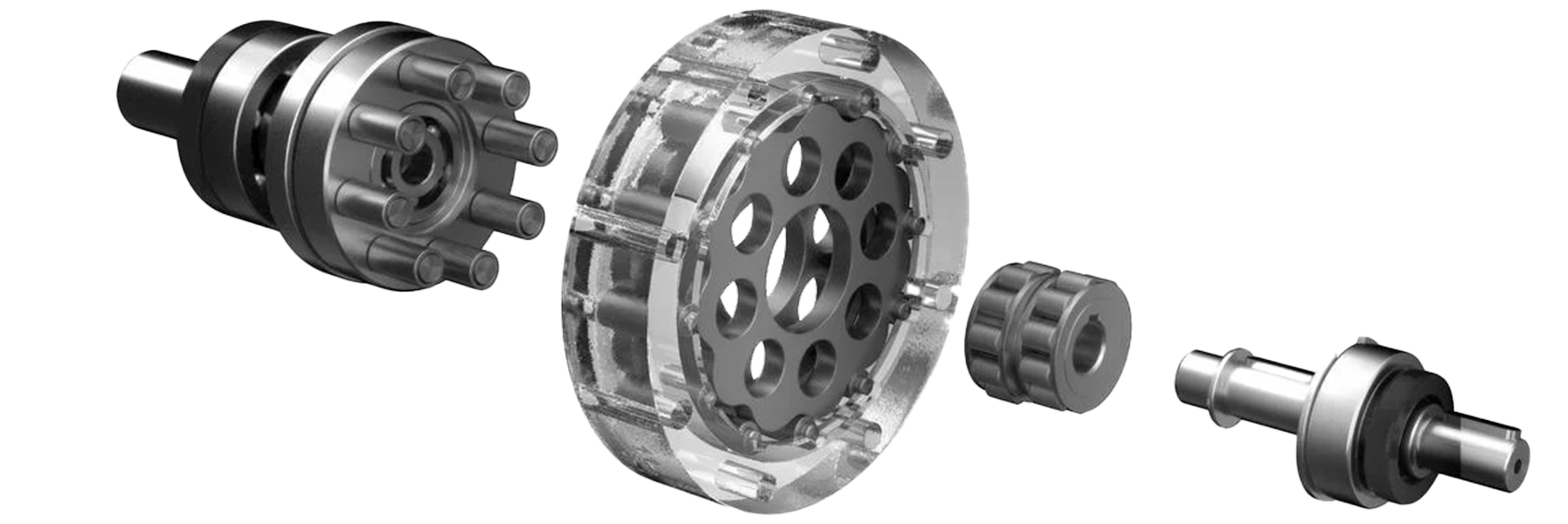

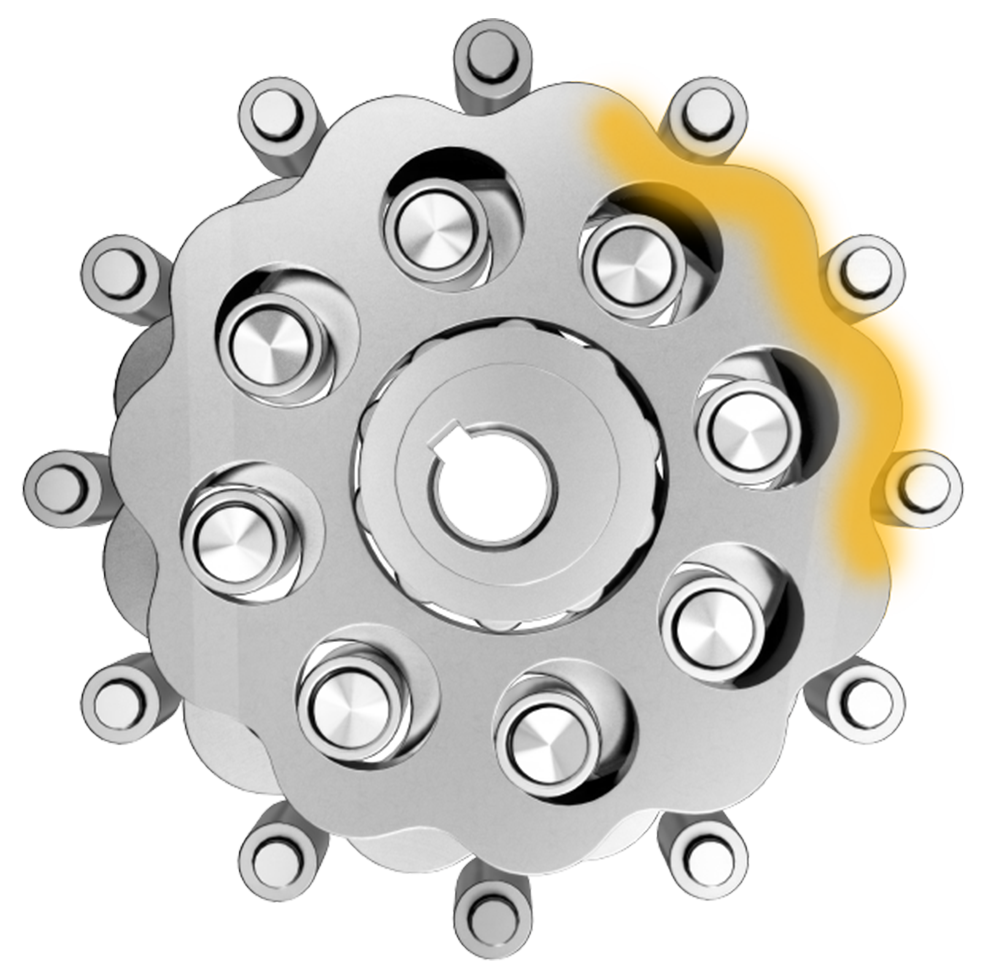

Cycloidal discs have a wave shaped rotation around a stationery ring gear housing. The lobes of the discs engage with the pins of the ring gear housing, which then rotate at a reduced speed. The reduction ratio is determined by the number of cycloidal lobes on the cycloidal disc. This rolling motion creates a gear that can effectively share the load better than a conventional cog gear.

How cycloidal gears work

What are the benefits of using cycloidal gears today?

Compact, durable and superior to conventional gears in many ways. They offer high reduction ratios with precision and very low backlash. Sharing the load across many contact points ensures its durability and ability to control large loads.

Read how Sumitomo Cyclo delivers benefits in applications around the worldSumitomo Cyclo gears are proven in a huge range of applications

As the inventor of cycloidal gears, we have been evolving and innovating with this technology for 100 years. Sumitomo Cyclo Gears are proven in applications including robust industrial gears, robotics, machine tools and medical technology. They are widely used in decanters and centrifuges; and are integrated into driverless transport systems and autonomous mobile robots around the world.

Explore our range of Cyclo gears, proven in applications around the world

Find out more

To discuss your potential applications of this technology please contact your local Sumitomo Cyclo expert.

Choose your country or region